>> Products Category

>> Contact Us

- Add: Jiaoxi town, Changzhou, Jiangsu, P.R. China

- Zipcode: 213116

- Tel: +86-519-88900500 88900909

- Fax: +86-519-88902563

- Email: brian@cndryer.com

prev

next

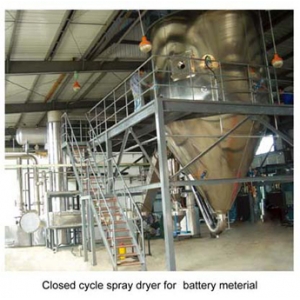

Closed cycle spray dryer

Description

Closed cycle spray drying in the drying chamber will be sealed into the mist droplets dispersed solid to liquid and hot medium (nitrogen N2) was dried droplet method of powder products. Atomized by rotary atomizer or a nozzle atomizer to achieve, droplet drying can be adjusted by the temperature or the flow of heat medium to be controlled, evaporation of the solvent to be recovered through the condensation unit, after "removal" and full " dewetting "of the media were highly efficient filters and returned to heat exchanger, and finally recycled into the drying system.

The success of closed cycle spray drying washing and cooling operation requirements will be part of an accurate temperature control. For high boiling point of alcohol generally cooling water or salt water, low boiling point solvents such as dichloromethane, hexane, acetone and the like, you must use compression refrigeration system heat exchange

- Product Details

- Inquire Now

| Feature | ||

|

||

|

||

|

||

| Product applications | ||

| 1.Non-oxide ceramics (AlN, Si3N4 etc.), hard metal powders, high-performance battery meterial,etc. 2.Flavoring material, health products. 3.Medicinal product, vitamin, organic medicines. 4.Synthetic resin, paraffin wax. |

||

| In the field of carbide applications, all closed cycle spray dryers for production of carbides (hard metal powders) are pre-erected and pressure tested before shipment. | ||

|

||

-

*Subject:

-

Your Name:

-

Tel Number:

-

*Your E-Mail:

-

*Content:Note:HTML is not translated!