- Add: Jiaoxi town, Changzhou, Jiangsu, P.R. China

- Zipcode: 213116

- Tel: +86-519-88900500 88900909

- Fax: +86-519-88902563

- Email: brian@cndryer.com

- Product Details

- Inquire Now

Product Description

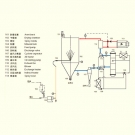

“xian dao” Pilot spray dryer has enjoyed unique success ever since it was first introduced to our customers. more than 200units have been supplied to universities. research centers, and specialist Powder Production facilities around the world.

It has been introduced to meet the still increasing demand for a more flexible, reliable, modern and easy -to -handle laboratory dryer having different levels of control systems.

Same time, spray drying is a unique drying process involving both particle formation and drying. The powder characteristics can be controlled and powder properties maintained. Constant throughout a continuous operation. The selection and operation of the atomizer is of extreme importance in achieving an optimum.

|

Rotary atomizer

|

Co-current two-fluid nozzle

|

Fountain two fluid nozzle

|

-

*Subject:

-

Your Name:

-

Tel Number:

-

*Your E-Mail:

-

*Content:Note:HTML is not translated!